Mg500 Slewing Bearing for Reduktor

Basic Info

Model No.: MG500

Product Description

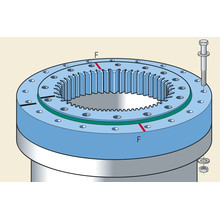

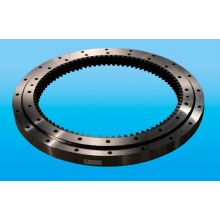

Model NO.: MG500 The Number of Rows: Single Material: 42CrMo Load Direction: Radial Bearing Brand: Lyhy Company History: Since 2000 Gear Type: External Gear Trademark: LYHY Origin: Luoyang City, China Rolling Body: Ball Bearings Outer Dimension: 200-6500mm Spherical: Non-Aligning Bearings Separated: Unseparated Custom Design: Available Testing: in House Gear Hardness: HRC50-55 Specification: need to be discussed HS Code: 848210900 Slewing Bearing MG500 with internal gear , following is the detailed technical parameter for this slewing bearing

1. Type: single row four point contact ball

2. Bore diameter: 772mm

3. Outside diameter: 916mm

4. Height: 52mm

5. Material: 42CrMo

6. Precision: P0. P6. P5.

7. Cage/retainer: Nylon or aluminum

8. Gear type: internal gear, gear grade 7.5GK

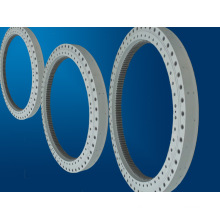

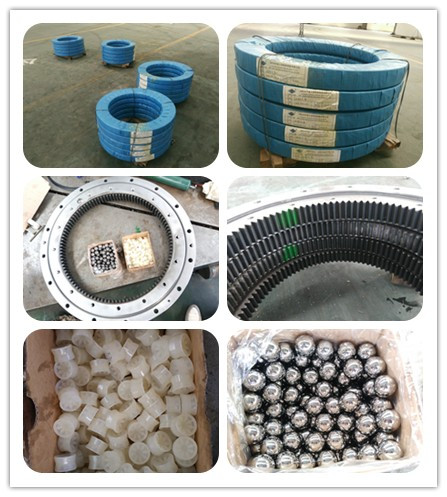

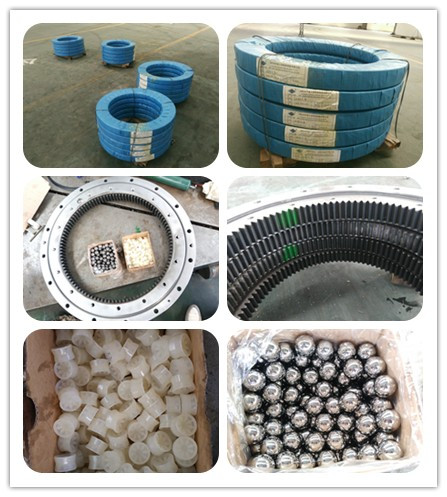

Packing

1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to invoid the rust or the moist;

4. We can depend on the customers demand to be packed;

About LYHY bearings

1.introduction:we are a manufacturer of slewing bearing since 1993, our factory occupies a area of 30000square meters with 4 workshop and 1 office building.

2. Featured products: slewing bearing and slewing drive

3. Capital: Current is 1 million RMB, but we are increasing the capital to 10 million RMB

4. Workers: 40

5. Certificate: ISO9001:2008, 3.1 certificate, CCS certificate, Science and Technology Progress Award

6. Annual Exportation: 8million USD

7. Exported countries: (39)

Asia: India, Pakistan, Iran, Signore, Georgia, Malaysia, Vietnam, Thailand, Philippines, Israel, Korea, UAE, Sri Lanka, Saudi Arabia,

Europe: Turkey, Russia, Spain, Czech Republic, Italy, Poland, Slovakia, Bosnia and Herzegovina, Austria, France, Germany, Switzerland, Finland, Ukraine, UK

America: USA, Canada, Mexico, Brazil, Puerto Rico, Peru, Chile

Africa: South Africa, Egypt

Oceania: Australia

Slewing Bearing

1. Introduction of LYHY Slewing Ring Bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball slewing ring bearings, roller Slewing Bearings and precision slewing ring bearings as per customer's different technical requirements.

Slewing ring bearing is also called slewing ring, slewing bearing, turntable bearing, and rotary bearing.

Slewing ring bearing is a bearing that able to bear axial load, radial load and overturning torque. Under normal circumstances, slewing ring bearings have their own mounting holes, lubricant holes and seal holes, to meet the different needs of the various host working under the various conditions;

On the other hand, slewing ring bearing itself has characteristics of compact structure, guide rotating convenient, easy to install and maintaining easily.

2. Structure

2.1 Slewing ring bearings have different types as per different structures, here below is what we offering now:

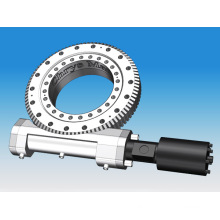

Single row ball slewing ring bearings

Double row ball slewing ring bearings

Crossed roller slewing ring bearings

Triple row roller slewing ring bearings

Flange slewing ring bearings

2.2 The above slewing ring bearings can also be divided into three different types as per different transmissions:

Slewing ring bearings with no gear

Slewing ring bearings with external gear

Slewing ring bearings with internal gear

3. Features:

Slewing ring bearings have more features: compact structure, reliable guide, simple installation, and easily maintenance

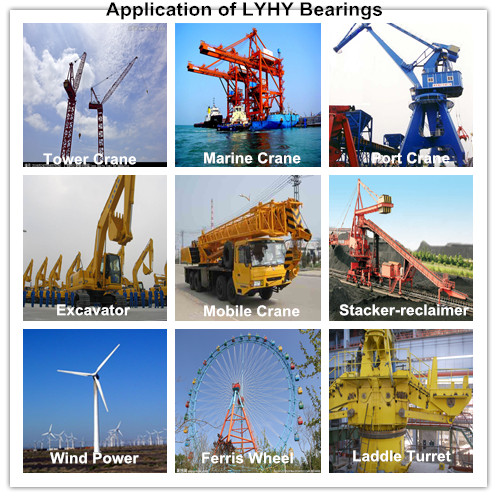

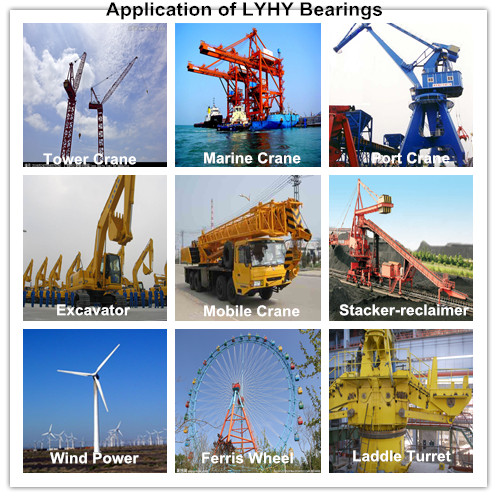

4. Application:

Slewing ring bearings can be widely used in lifting & transport machinery, mining machinery, construction machinery, port hoisting machinery, port oil transfer equipment, onshore and offshore crane, excavator, concrete machine, paper machine, plastic and rubber machine, weave machine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipments and other large rotary device.

Single row ball slewing ring bearing

1. Introduction of LYHY single row ball slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

The single row ball slewing ring bearing is composed of 2 seat-rings. The balls contact with the circular race at four points, via which the axial force, radial force and resultant moment may be born simultaneously.

2. Structure

Slewing ring bearings have different types as per different structures, here below is what we offering now:

Single row ball slewing bearing has three different types:

Single row ball slewing bearing with no gear

Single row ball slewing bearing with external gear

Single row ball slewing bearing with internal gear

3. Features

Single row ball slewing ring bearings have following features:

Compact in structure and light in weight.

4. Application:

Single row ball slewing ring bearings are widely used in slewing conveyers, welding arm and positioned, medium duty cranes, excavators and other engineering machines

Double row ball slewing ring bearing

1. Introduction of LYHY double row ball slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

The double row ball slewing bearing has three seat-rings. The steel balls and the retainers may be directly arranged into the upper and lower racers. Two rows of steel balls with different diameters are fitted according to the force. Such open type fitting is extraordinary convenient, the loading angels at upper and lower races are 90°which can carry both of the axial force and capsizing moment. When the radial force is larger than 1/10 of the axial force, the races should be newly designed.

2. Structure:

Double row ball slewing bearing has three different types:

Double row ball slewing bearing with no gear

Double row ball slewing bearing with external gear

Double row ball slewing bearing with internal gear

3. Features:

Double row ball slewing ring bearings have following features:

Larger dimension of axial and radial and compact structure.

4. Application:

Double row ball slewing ring bearings are widely used in Tower cranes which require working radius over medium range, auto crane and loading (unloading) machinery.

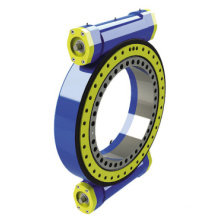

Crossed roller slewing ring bearing

1. Introduction of LYHY crossed roller slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

With the cross roller Ring, cylindrical rollers are arranged crosswise, with each roller perpendicular to the adjacent roller, in a 90° groove, separated from each other by a spacer retainer. This design allows just one bearing to receive loads in all directions including, radial, axial and moment loads. Since the Cross-Roller Ring achieves high rigidity despite the minimum possible dimensions of the inner and outer rings, it is optimal for applications such as joints and swiveling units of industrial robots, swiveling tables of machining centers, rotary units of manipulators, precision rotary tables, medical equipment, measuring instruments and IC manufacturing machines.

2. Structure:

Cross roller slewing bearing has three different types:

Cross roller ball slewing bearing with no gear

Cross roller ball slewing bearing with external gear

Cross roller ball slewing bearing with internal gear

3. Features

Cross roller slewing ring bearings have following features:

1. High precision: cross roller bearings can be made high precision bearings, at P4, P2.

2. High rigidity: These series roller bearings are with preload.

3. High load capacity: This series roller bearing can support axial load, radial load, and tilting load.

4. Small volume: this series roller bearing can save space for the machine.

4. Application

Cross roller slewing rings are widely applied in the precision rotary table, rotary joint of manipulator, medical equipment, and measuring instrument etc

Triple row roller slewing ring bearing

1. Introduction of LYHY triple row roller slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

Three row roller slewing ring bearing has three seat-rings, which separate the upper, lower and radial raceway, via which the load of each row of the rollers may be specified. Thus it can carry different load simultaneously and its load capacity is the largest one of the four types

2. Structure:

Triple row roller slewing bearing has three different types:

Triple row roller slewing bearing with no gear

Triple row roller slewing bearing with external gear

Triple row roller slewing bearing with internal gear

3. Features

Triple row roller slewing ring bearings have following features:

Larger axial and radial dimension, compact structure

4. Application

Triple row roller slewing rings are widely used in heavy-duty machines which require large working radius, such as bucket-wheel excavators, wheeled cranes, ship cranes, ladle turret, auto cranes etc.

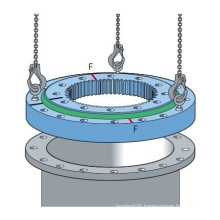

Flange Slewing Bearing

1. Introduction of LYHY flange slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

Flange slewing bearing is a special slewing ring bearing, it can have one flange in the outer ring, or one flange in the inner ring, even it can have one flange in both inner ring and outer ring.

2. Structure:

Flange slewing bearing has three different types:

Flange slewing bearing with no gear

Flange slewing bearing with external gear

Flange slewing bearing with internal gear

3. Features

Flange slewing bearings have following features:

Compact structure and easily installment.

4. Application

Flange slewing bearings are widely used in tow truck, and other applications are the same as slewing bearings, such as lifting & transport machinery, mining machinery, construction machinery, excavator, concrete machine, paper machine, plastic and rubber machine and steel plant.

Excavator Slewing Bearing

1. Introduction of LYHY excavator slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

Excavator slewing bearing is a special slewing ring bearing as per its applications. And it is a very important part for excavators, we can supply excavator slewing bearings for both second-hand excavators for maintenance and new excavators.

2. Structure:

Excavator slewing bearing are usually made as per single row ball slewing bearing structure, and most of them are internal gear types, but some are external gear types.

3. Features

Excavator slewing bearings have familiar features as single row ball slewing ring bearings.

Compact structure, light weight and easily installment.

4. Application

Excavator slewing bearings are widely used for all brands of excavators, such as Komatsu, Hitachi, Kobelco, Sumitomo, Doosan, Hyundai, Samsung, Caterpillar, Daewoo, Kato, Volvo, and so on.

Contact us if you need more details on Slewing Bearing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Slewing Ring Bearings、Slewing Ring. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Type: single row four point contact ball

2. Bore diameter: 772mm

3. Outside diameter: 916mm

4. Height: 52mm

5. Material: 42CrMo

6. Precision: P0. P6. P5.

7. Cage/retainer: Nylon or aluminum

8. Gear type: internal gear, gear grade 7.5GK

Packing

1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to invoid the rust or the moist;

4. We can depend on the customers demand to be packed;

About LYHY bearings

1.introduction:we are a manufacturer of slewing bearing since 1993, our factory occupies a area of 30000square meters with 4 workshop and 1 office building.

2. Featured products: slewing bearing and slewing drive

3. Capital: Current is 1 million RMB, but we are increasing the capital to 10 million RMB

4. Workers: 40

5. Certificate: ISO9001:2008, 3.1 certificate, CCS certificate, Science and Technology Progress Award

6. Annual Exportation: 8million USD

7. Exported countries: (39)

Asia: India, Pakistan, Iran, Signore, Georgia, Malaysia, Vietnam, Thailand, Philippines, Israel, Korea, UAE, Sri Lanka, Saudi Arabia,

Europe: Turkey, Russia, Spain, Czech Republic, Italy, Poland, Slovakia, Bosnia and Herzegovina, Austria, France, Germany, Switzerland, Finland, Ukraine, UK

America: USA, Canada, Mexico, Brazil, Puerto Rico, Peru, Chile

Africa: South Africa, Egypt

Oceania: Australia

Slewing Bearing

1. Introduction of LYHY Slewing Ring Bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball slewing ring bearings, roller Slewing Bearings and precision slewing ring bearings as per customer's different technical requirements.

Slewing ring bearing is also called slewing ring, slewing bearing, turntable bearing, and rotary bearing.

Slewing ring bearing is a bearing that able to bear axial load, radial load and overturning torque. Under normal circumstances, slewing ring bearings have their own mounting holes, lubricant holes and seal holes, to meet the different needs of the various host working under the various conditions;

On the other hand, slewing ring bearing itself has characteristics of compact structure, guide rotating convenient, easy to install and maintaining easily.

2. Structure

2.1 Slewing ring bearings have different types as per different structures, here below is what we offering now:

Single row ball slewing ring bearings

Double row ball slewing ring bearings

Crossed roller slewing ring bearings

Triple row roller slewing ring bearings

Flange slewing ring bearings

2.2 The above slewing ring bearings can also be divided into three different types as per different transmissions:

Slewing ring bearings with no gear

Slewing ring bearings with external gear

Slewing ring bearings with internal gear

3. Features:

Slewing ring bearings have more features: compact structure, reliable guide, simple installation, and easily maintenance

4. Application:

Slewing ring bearings can be widely used in lifting & transport machinery, mining machinery, construction machinery, port hoisting machinery, port oil transfer equipment, onshore and offshore crane, excavator, concrete machine, paper machine, plastic and rubber machine, weave machine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipments and other large rotary device.

Single row ball slewing ring bearing

1. Introduction of LYHY single row ball slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

The single row ball slewing ring bearing is composed of 2 seat-rings. The balls contact with the circular race at four points, via which the axial force, radial force and resultant moment may be born simultaneously.

2. Structure

Slewing ring bearings have different types as per different structures, here below is what we offering now:

Single row ball slewing bearing has three different types:

Single row ball slewing bearing with no gear

Single row ball slewing bearing with external gear

Single row ball slewing bearing with internal gear

3. Features

Single row ball slewing ring bearings have following features:

Compact in structure and light in weight.

4. Application:

Single row ball slewing ring bearings are widely used in slewing conveyers, welding arm and positioned, medium duty cranes, excavators and other engineering machines

Double row ball slewing ring bearing

1. Introduction of LYHY double row ball slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

The double row ball slewing bearing has three seat-rings. The steel balls and the retainers may be directly arranged into the upper and lower racers. Two rows of steel balls with different diameters are fitted according to the force. Such open type fitting is extraordinary convenient, the loading angels at upper and lower races are 90°which can carry both of the axial force and capsizing moment. When the radial force is larger than 1/10 of the axial force, the races should be newly designed.

2. Structure:

Double row ball slewing bearing has three different types:

Double row ball slewing bearing with no gear

Double row ball slewing bearing with external gear

Double row ball slewing bearing with internal gear

3. Features:

Double row ball slewing ring bearings have following features:

Larger dimension of axial and radial and compact structure.

4. Application:

Double row ball slewing ring bearings are widely used in Tower cranes which require working radius over medium range, auto crane and loading (unloading) machinery.

Crossed roller slewing ring bearing

1. Introduction of LYHY crossed roller slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

With the cross roller Ring, cylindrical rollers are arranged crosswise, with each roller perpendicular to the adjacent roller, in a 90° groove, separated from each other by a spacer retainer. This design allows just one bearing to receive loads in all directions including, radial, axial and moment loads. Since the Cross-Roller Ring achieves high rigidity despite the minimum possible dimensions of the inner and outer rings, it is optimal for applications such as joints and swiveling units of industrial robots, swiveling tables of machining centers, rotary units of manipulators, precision rotary tables, medical equipment, measuring instruments and IC manufacturing machines.

2. Structure:

Cross roller slewing bearing has three different types:

Cross roller ball slewing bearing with no gear

Cross roller ball slewing bearing with external gear

Cross roller ball slewing bearing with internal gear

3. Features

Cross roller slewing ring bearings have following features:

1. High precision: cross roller bearings can be made high precision bearings, at P4, P2.

2. High rigidity: These series roller bearings are with preload.

3. High load capacity: This series roller bearing can support axial load, radial load, and tilting load.

4. Small volume: this series roller bearing can save space for the machine.

4. Application

Cross roller slewing rings are widely applied in the precision rotary table, rotary joint of manipulator, medical equipment, and measuring instrument etc

Triple row roller slewing ring bearing

1. Introduction of LYHY triple row roller slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

Three row roller slewing ring bearing has three seat-rings, which separate the upper, lower and radial raceway, via which the load of each row of the rollers may be specified. Thus it can carry different load simultaneously and its load capacity is the largest one of the four types

2. Structure:

Triple row roller slewing bearing has three different types:

Triple row roller slewing bearing with no gear

Triple row roller slewing bearing with external gear

Triple row roller slewing bearing with internal gear

3. Features

Triple row roller slewing ring bearings have following features:

Larger axial and radial dimension, compact structure

4. Application

Triple row roller slewing rings are widely used in heavy-duty machines which require large working radius, such as bucket-wheel excavators, wheeled cranes, ship cranes, ladle turret, auto cranes etc.

Flange Slewing Bearing

1. Introduction of LYHY flange slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

Flange slewing bearing is a special slewing ring bearing, it can have one flange in the outer ring, or one flange in the inner ring, even it can have one flange in both inner ring and outer ring.

2. Structure:

Flange slewing bearing has three different types:

Flange slewing bearing with no gear

Flange slewing bearing with external gear

Flange slewing bearing with internal gear

3. Features

Flange slewing bearings have following features:

Compact structure and easily installment.

4. Application

Flange slewing bearings are widely used in tow truck, and other applications are the same as slewing bearings, such as lifting & transport machinery, mining machinery, construction machinery, excavator, concrete machine, paper machine, plastic and rubber machine and steel plant.

Excavator Slewing Bearing

1. Introduction of LYHY excavator slewing bearings

LYHY is a professional manufacturer in slewing ring bearings since 1993. We can also design and make other standard and non-standard ball bearings, roller bearings and precision bearings as per customer's different technical requirements.

Slewing bearing is also called slewing ring, slewing ring bearing, turntable bearing, and rotary bearing.

Excavator slewing bearing is a special slewing ring bearing as per its applications. And it is a very important part for excavators, we can supply excavator slewing bearings for both second-hand excavators for maintenance and new excavators.

2. Structure:

Excavator slewing bearing are usually made as per single row ball slewing bearing structure, and most of them are internal gear types, but some are external gear types.

3. Features

Excavator slewing bearings have familiar features as single row ball slewing ring bearings.

Compact structure, light weight and easily installment.

4. Application

Excavator slewing bearings are widely used for all brands of excavators, such as Komatsu, Hitachi, Kobelco, Sumitomo, Doosan, Hyundai, Samsung, Caterpillar, Daewoo, Kato, Volvo, and so on.

| Model | Overall Dimension | Mounting Dimension | Structure Dimension | Gear Parameter | External Gear | Internal Gear | Load | Weight | ||||||||||||||||

| None gear | External Gear | Internal Gear | D | d | H | D1 | D2 | N | φ | M | D3 | d1 | H1 | h | n1 | b | X | m | Da | Z | da | Z | 104kN | kg |

| mm | mm | mm | mm | mm | mm | |||||||||||||||||||

| 010.20.200 | 011.20.200 | / | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 199 | 201 | 50 | 10 | 2 | 40 | 0 | 3 | 300 | 98 | / | / | / | / |

| 010.20.224 | 011.20.224 | / | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 223 | 225 | 50 | 10 | 2 | 40 | 0 | 3 | 321 | 105 | / | / | / | / |

| 010.20.250 | 011.20.250 | / | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 249 | 251 | 50 | 10 | 2 | 40 | 0 | 4 | 352 | 86 | / | / | / | / |

| 010.20.280 | 011.20.280 | / | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 279 | 281 | 50 | 10 | 2 | 40 | 0 | 4 | 384 | 94 | / | / | / | / |

| 010.25.315 | 011.25.315 | 013.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 314 | 316 | 60 | 10 | 2 | 50 | 0 | 5 | 435 | 85 | 190 | 40 | / | / |

| 010.25.355 | 011.25.355 | 013.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 354 | 356 | 60 | 10 | 2 | 50 | 0 | 5 | 475 | 93 | 235 | 49 | / | / |

| 010.25.400 | 011.25.400 | 013.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 399 | 401 | 60 | 10 | 2 | 50 | 0 | 6 | 528 | 86 | 276 | 48 | / | / |

| 010.25.450 | 011.25.450 | 013.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 449 | 451 | 60 | 10 | 2 | 50 | 0 | 6 | 576 | 94 | 324 | 56 | / | / |

| 010.30.500 | 011.30.500 | 013.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 498.5 | 501.5 | 70 | 10 | 4 | 60 | 0.5 | 5 | 630 | 123 | 365 | 74 | 129 | 75.8 |

| 012.30.500 | 014.30.500 | 6 | 630 | 102 | 366 | 62 | 129 | 75.8 | ||||||||||||||||

| 010.25.500 | 011.25.500 | 013.25.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 498.5 | 501.5 | 70 | 10 | 4 | 60 | 0.5 | 5 | 630 | 123 | 365 | 74 | 129 | 75.8 |

| 012.25.500 | 014.25.500 | 6 | 630 | 102 | 366 | 62 | 129 | 75.8 | ||||||||||||||||

| 010.30.560 | 011.30.560 | 013.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 558.5 | 561.5 | 70 | 10 | 4 | 60 | 0.5 | 5 | 690 | 135 | 425 | 86 | 144 | 94 |

| 012.30.560 | 014.30.560 | 6 | 690 | 112 | 426.5 | 72 | 144 | 94 | ||||||||||||||||

| 010.25.560 | 011.25.560 | 013.25.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 558.5 | 561.5 | 70 | 10 | 4 | 60 | 0.5 | 5 | 690 | 135 | 425 | 86 | 144 | 94 |

| 012.25.560 | 014.25.560 | 6 | 690 | 112 | 426.5 | 72 | 144 | 94 | ||||||||||||||||

| 010.30.630 | 011.30.630 | 013.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 628.5 | 631.5 | 70 | 10 | 4 | 60 | 0.5 | 6 | 774 | 126 | 492 | 83 | 187 | 110 |

| 012.30.630 | 014.30.630 | 8 | 776 | 94 | 488 | 62 | 187 | 110 | ||||||||||||||||

| 010.25.630 | 011.25.630 | 013.25.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 628.5 | 631.5 | 70 | 10 | 4 | 60 | 0.5 | 6 | 774 | 126 | 492 | 83 | 187 | 110 |

| 012.25.630 | 014.25.630 | 8 | 776 | 94 | 488 | 62 | 187 | 110 | ||||||||||||||||

| 010.30.710 | 011.30.710 | 013.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 708.5 | 711.5 | 70 | 10 | 4 | 60 | 0.5 | 6 | 852 | 139 | 570 | 86 | 212 | 120 |

| 012.30.710 | 014.30.710 | 8 | 856 | 104 | 568 | 72 | 212 | 120 | ||||||||||||||||

| 010.25.710 | 011.25.710 | 013.25.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 708.5 | 711.5 | 70 | 10 | 4 | 60 | 0.5 | 6 | 852 | 139 | 570 | 86 | 212 | 120 |

| 012.30.710 | 014.25.710 | 8 | 856 | 104 | 568 | 72 | 212 | 120 | ||||||||||||||||

| 010.30.955.11 | / | / | 1098 | 893 | 90 | 1060 | 845 | 48/ 47 | 22 | M20 | 956.5 | 953.5 | 71 | 19 | 6 | / | / | / | / | / | / | / | 270 | 126 |

| 010.40.800 | 011.40.800 | 013.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 198.5 | 801.5 | 90 | 10 | 6 | 80 | 0.5 | 8 | 968 | 118 | 632 | 80 | 313 | 256 |

| 012.40.800 | 014.40.800 | 10 | 970 | 94 | 630 | 64 | 313 | 256 | ||||||||||||||||

| 010.30.800 | 011.30.800 | 013.30.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 198.5 | 801.5 | 90 | 10 | 6 | 80 | 0.5 | 8 | 968 | 118 | 632 | 80 | 313 | 256 |

| 012.30.800 | 014.30.800 | 10 | 970 | 94 | 630 | 64 | 313 | 256 | ||||||||||||||||

| 010.40.900 | 011.40.900 | 013.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 898.5 | 901.5 | 90 | 10 | 6 | 80 | 0.5 | 8 | 1064 | 130 | 736 | 93 | 355 | 240 |

| 012.40.900 | 014.40.900 | 10 | 1070 | 104 | 730 | 74 | 355 | 240 | ||||||||||||||||

| 010.30.900 | 011.30.900 | 013.30.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 898.5 | 901.5 | 90 | 10 | 6 | 80 | 0.5 | 8 | 1064 | 130 | 736 | 93 | 355 | 240 |

| 012.30.900 | 014.30.900 | 10 | 1070 | 104 | 730 | 74 | 355 | 240 | ||||||||||||||||

| 010.40.1000 | 011.40.1000 | 013.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M30 | 998.5 | 1001.5 | 90 | 10 | 6 | 80 | 0.5 | 10 | 1190 | 116 | 820 | 83 | 394 | 305 |

| 012.40.1000 | 014.40.1000 | 12 | 1188 | 96 | 816 | 69 | 394 | 305 | ||||||||||||||||

| 010.30.1000 | 011.30.1000 | 013.30.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M30 | 998.5 | 1001.5 | 90 | 10 | 6 | 80 | 0.5 | 10 | 1190 | 116 | 820 | 83 | 394 | 305 |

| 012.30.1000 | 014.30.1000 | 12 | 1188 | 96 | 816 | 69 | 394 | 305 | ||||||||||||||||

| 010.40.1120 | 011.40.1120 | 013.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M30 | 1118 | 1122 | 90 | 10 | 6 | 80 | 0.5 | 10 | 1300 | 127 | 940 | 95 | 443 | 300 |

| 012.40.1120 | 014.40.1120 | 12 | 1308 | 106 | 936 | 79 | 443 | 300 | ||||||||||||||||

| 011.40.1120.12K | / | 1242 | 998 | 100 | 1198 | 1042 | 18 | 22 | M30 | 1118.5 | 1121.5 | 90 | 10 | 6 | 80 | 0.5 | 10 | 1300 | 127 | / | / | 334 | 352 | |

| 012.40.1120.12K1 | / | 36 | 1118 | 1121 | 10 | 1298 | 127 | / | / | 334 | 334 | |||||||||||||

| 010.30.1120 | 011.30.1120 | 013.30.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M30 | 1118 | 1122 | 90 | 10 | 6 | 80 | 0.5 | 10 | 1300 | 127 | 940 | 95 | 443 | 300 |

| 012.30.1120 | 014.30.1120 | 12 | 1308 | 106 | 936 | 79 | 443 | 300 | ||||||||||||||||

| 010.45.1250 | 011.45.1250 | 013.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M42 | 1248 | 1252 | 100 | 10 | 6 | 90 | 0.5 | 12 | 1452 | 118 | 1044 | 88 | 554 | 420 |

| 011.45.1250 | 014.45.1250 | 90 | 0.5 | 14 | 1456 | 101 | 1036 | 75 | 554 | 420 | ||||||||||||||

| 010.35.1250 | 011.35.1250 | 013.35.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M42 | 1248 | 1252 | 100 | 10 | 6 | 90 | 0.5 | 12 | 1452 | 118 | 1044 | 88 | 554 | 420 |

| 011.35.1250 | 014.35.1250 | 90 | 0.5 | 14 | 1456 | 101 | 1036 | 75 | 554 | 420 | ||||||||||||||

| 010.45.1400 | 011.45.1400 | 013.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M42 | 1398 | 1402 | 100 | 10 | 6 | 90 | 0.5 | 12 | 1608 | 131 | 1188 | 100 | 617 | 480 |

| 012.45.1400 | 014.45.1400 | 90 | 0.5 | 14 | 1610 | 112 | 1190 | 86 | 617 | 480 | ||||||||||||||

| 010.35.1400 | 011.35.1400 | 013.35.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M42 | 1398 | 1402 | 100 | 10 | 6 | 90 | 0.5 | 12 | 1608 | 131 | 1188 | 100 | 617 | 480 |

| 012.35.1400 | 014.35.1400 | 90 | 0.5 | 14 | 1610 | 112 | 1190 | 86 | 617 | 480 | ||||||||||||||

| 010.45.1600 | 011.45.1600 | 013.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M42 | 1598 | 1602 | 100 | 10 | 6 | 90 | 0.5 | 14 | 1820 | 127 | 1386 | 100 | 702 | 550 |

| 012.45.1600 | 014.45.1600 | 90 | 0.5 | 16 | 1824 | 111 | 1376 | 87 | 702 | 550 | ||||||||||||||

| 010.35.1600 | 011.35.1600 | 013.35.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M42 | 1598 | 1602 | 100 | 10 | 6 | 90 | 0.5 | 14 | 1820 | 127 | 1386 | 100 | 702 | 550 |

| 012.35.1600 | 014.35.1600 | 90 | 0.5 | 16 | 1824 | 111 | 1376 | 87 | 702 | 550 | ||||||||||||||

| 010.45.1800 | 011.45.1800 | 013.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M42 | 1798 | 1802 | 100 | 10 | 8 | 90 | 0.5 | 14 | 2016 | 141 | 1568 | 113 | 793 | 610 |

| 012.45.1800 | 014.45.1800 | 90 | 0.5 | 16 | 2016 | 123 | 1568 | 99 | 793 | 610 | ||||||||||||||

| 011.45.1800.05 | / | 1660 | 110 | 1887 | 1713 | 45 | 26 | M42 | 1798 | 1802 | 100 | 10 | 5 | 100 | 0.5 | 14 | 2016 | 141 | / | / | 594 | 684 | ||

| 010.35.1800 | 011.35.1800 | 013.35.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M42 | 1798 | 1802 | 100 | 10 | 8 | 90 | 0.5 | 14 | 2016 | 141 | 1568 | 113 | 793 | 610 |

| 012.35.1800 | 014.35.1800 | 90 | 0.5 | 16 | 2016 | 123 | 1568 | 99 | 793 | 610 | ||||||||||||||

| 010.60.2000 | 011.60.2000 | 013.60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 1998 | 2002 | 132 | 12 | 8 | 120 | 0.5 | 16 | 2272 | 139 | 1728 | 109 | 1210 | 1100 |

| 012.60.2000 | 014.60.2000 | 120 | 0.5 | 18 | 2268 | 123 | 1728 | 97 | 1210 | 1100 | ||||||||||||||

| 012.60.2000.12K | / | / | / | / | 2160 | 1825 | 45 | 33 | M30 | 1998 | 2002 | 132 | 12 | 8 | 120 | 0.5 | 16 | 2240 | 139 | / | / | 1122 | 970 | |

| 010.40.2000 | 011.40.2000 | 013.40.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 1998 | 2002 | 132 | 12 | 8 | 120 | 0.5 | 16 | 2272 | 139 | 1728 | 109 | 1210 | 1100 |

| 012.40.2000 | 014.40.2000 | 120 | 0.5 | 18 | 2268 | 123 | 1728 | 97 | 1210 | 1100 | ||||||||||||||

| 010.60.2240 | 011.60.2240 | 013.60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 2237.5 | 2245.5 | 132 | 12 | 8 | 120 | 0.5 | 16 | 2496 | 153 | 1984 | 125 | 1350 | 1250 |

| 012.60.2240 | 014.60.2240 | 120 | 0.5 | 18 | 2502 | 136 | 1980 | 111 | 1350 | 1250 | ||||||||||||||

| 010.40.2240 | 011.40.2240 | 013.40.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 2237.5 | 2245.5 | 132 | 12 | 8 | 120 | 0.5 | 16 | 2496 | 153 | 1984 | 125 | 1350 | 1250 |

| 012.40.2240 | 014.40.2240 | 120 | 0.5 | 18 | 2502 | 136 | 1980 | 111 | 1350 | 1250 | ||||||||||||||

| 010.60.2500 | 011.60.2500 | 013.60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 2497.5 | 2502.5 | 132 | 12 | 8 | 120 | 0.5 | 18 | 2772 | 151 | 2332 | 125 | 1500 | 1400 |

| 012.60.2500 | 014.60.2500 | 120 | 0.5 | 20 | 2780 | 136 | 2220 | 112 | 1500 | 1400 | ||||||||||||||

| 010.40.2500 | 011.40.2500 | 013.40.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 2497.5 | 2502.5 | 132 | 12 | 8 | 120 | 0.5 | 18 | 2772 | 151 | 2332 | 125 | 1500 | 1400 |

| 012.40.2500 | 014.40.2500 | 120 | 0.5 | 20 | 2780 | 136 | 2220 | 112 | 1500 | 1400 | ||||||||||||||

| 010.60.2800 | 011.60.2800 | 013.60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 2797.5 | 2802.5 | 132 | 12 | 8 | 120 | 0.5 | 18 | 3078 | 168 | 2520 | 141 | 1680 | 1600 |

| 012.60.2800 | 014.60.2800 | 120 | 0.5 | 20 | 3080 | 151 | 2520 | 127 | 1680 | 1600 | ||||||||||||||

| 010.40.2800 | 011.40.2800 | 013.40.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 2797.5 | 2802.5 | 132 | 12 | 8 | 120 | 0.5 | 18 | 3078 | 168 | 2520 | 141 | 1680 | 1600 |

| 012.40.2800 | 014.40.2800 | 120 | 0.5 | 20 | 3080 | 151 | 2520 | 127 | 1680 | 1600 | ||||||||||||||

| 010.75.3150 | 011.75.3150 | 013.75.3150 | 3376 | 2922 | 144 | 3286 | 3014 | 56 | 45 | M42 | 3147.5 | 3152.5 | 162 | 12 | 8 | 150 | 0.5 | 20 | 3480 | 171 | 2820 | 142 | 2380 | 2800 |

| 012.75.3150 | 014.75.3150 | 150 | 0.5 | 22 | 3476 | 115 | 2816 | 129 | 2380 | 2800 | ||||||||||||||

| 010.50.3150 | 011.50.3150 | 013.50.3150 | 3376 | 2922 | 144 | 3286 | 3014 | 56 | 45 | M42 | 3147.5 | 3152.5 | 162 | 12 | 8 | 150 | 0.5 | 20 | 3480 | 171 | 2820 | 142 | 2380 | 2800 |

| 012.50.3150 | 014.50.3150 | 150 | 0.5 | 22 | 3476 | 115 | 2816 | 129 | 2380 | 2800 | ||||||||||||||

| 010.75.3550 | 011.75.3550 | 013.75.3550 | 3776 | 3322 | 144 | 3686 | 3414 | 56 | 45 | M42 | 3547.5 | 3552.5 | 162 | 12 | 8 | 150 | 0.5 | 20 | 3880 | 191 | 3220 | 162 | 2690 | 3200 |

| 012.75.3550 | 014.75.3550 | 150 | 0.5 | 22 | 3894 | 174 | 3212 | 147 | 2690 | 3200 | ||||||||||||||

| 010.50.3550 | 011.50.3550 | 013.50.3550 | 3776 | 3322 | 144 | 3686 | 3414 | 56 | 45 | M42 | 3547.5 | 3552.5 | 162 | 12 | 8 | 150 | 0.5 | 20 | 3880 | 191 | 3220 | 162 | 2690 | 3200 |

| 012.50.3550 | 014.50.3550 | 150 | 0.5 | 22 | 3894 | 174 | 3212 | 147 | 2690 | 3200 | ||||||||||||||

| 010.75.4000 | 011.75.4000 | 013.75.4000 | 4226 | 3772 | 144 | 4136 | 3864 | 60 | 45 | M42 | 3997.5 | 4002.5 | 162 | 12 | 10 | 150 | 0.5 | 22 | 4334 | 194 | 3652 | 167 | 3020 | 3600 |

| 012.75.4000 | 014.75.4000 | 150 | 0.5 | 25 | 4350 | 171 | 3650 | 147 | 3020 | 3600 | ||||||||||||||

| 010.50.4000 | 011.50.4000 | 013.50.4000 | 4226 | 3772 | 144 | 4136 | 3864 | 60 | 45 | M42 | 3997.5 | 4002.5 | 162 | 12 | 10 | 150 | 0.5 | 22 | 4334 | 194 | 3652 | 167 | 3020 | 3600 |

| 012.50.4000 | 014.50.4000 | 150 | 0.5 | 25 | 4350 | 171 | 3650 | 147 | 3020 | 3600 | ||||||||||||||

| 010.75.4500 | 011.75.4500 | 013.75.4500 | 4726 | 4272 | 144 | 4636 | 4364 | 60 | 45 | M42 | 4497.5 | 4502.5 | 162 | 12 | 8 | 150 | 0.5 | 22 | 4840 | 271 | 4158 | 190 | 3410 | 4000 |

| 012.75.4500 | 014.75.4500 | 150 | 0.5 | 25 | 4850 | 191 | 4150 | 167 | 3410 | 4000 | ||||||||||||||

| 010.50.4500 | 011.50.4500 | 013.50.4500 | 4726 | 4272 | 144 | 4636 | 4364 | 60 | 45 | M42 | 4497.5 | 4502.5 | 162 | 12 | 8 | 150 | 0.5 | 22 | 4840 | 271 | 4158 | 190 | 3410 | 4000 |

| 012.50.4500 | 014.50.4500 | 150 | 0.5 | 25 | 4850 | 191 | 4150 | 167 | 3410 | 4000 | ||||||||||||||

Contact us if you need more details on Slewing Bearing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Slewing Ring Bearings、Slewing Ring. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Slewing Bearing > Anti-corrosion Slewing Bearing

Premium Related Products

Other Products

Hot Products

Swing Bearing with Black Epoxy Paint Treatment (010.22.1588)Worm Drive for Worm Gear Box 12inchSlewing Bearing for Komatsu Excavator PC200-5Slewing Bearing with Dual Flange Side 010.20.747Four Point Contact Ball Slewing Ring Bearing for Boom Truck440c Stainless Steel Bearing SSR09zz SSR09-2RS SSR0zz Ssro-2RSRadial Spherical Plain Bearing Ge5e Ge6e Ge8e Ge10e Ge12eHigh Precision Tracking Roller Bearings (NUTR20 52)All Types of Pillow Blcok Bearings (UCP 208-1-1/2)Lm35uu Bearings/ Linear Bearings (Lm 35uu)Cylindrical Roller Bearing (NU204E 32504E N204E NF204E NJ204E NUP204E)Cheap Price Chrome Steel Deep Groove Ball Bearings (6000 series)High Precision Spherical Roller Bearings 23032 24032ca 24132caHigh Quality Timken Chrome Steel Taper Roller Bearings (25590/20)